Description

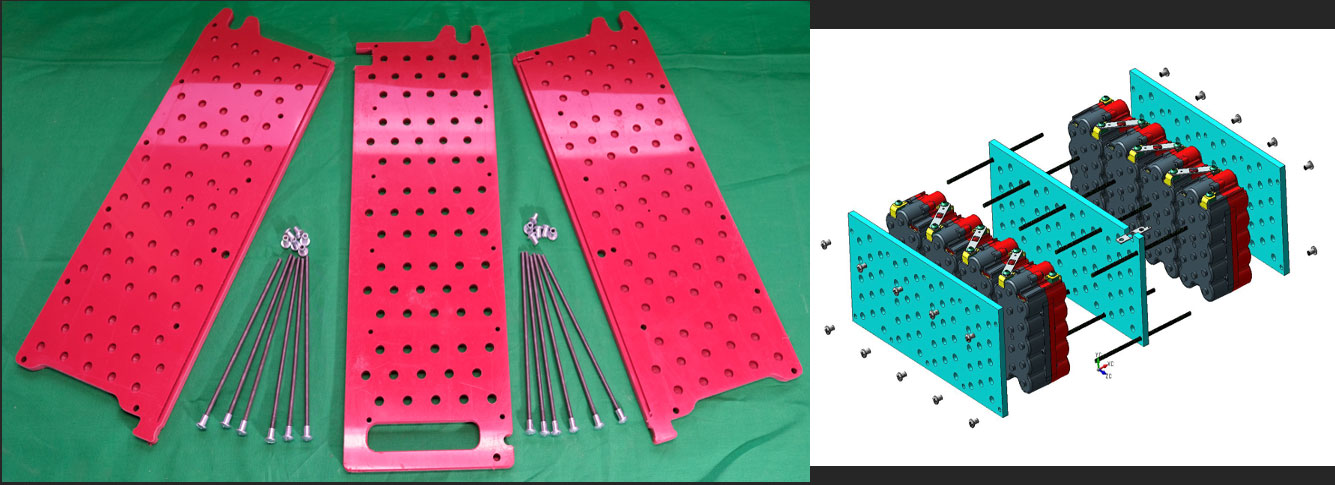

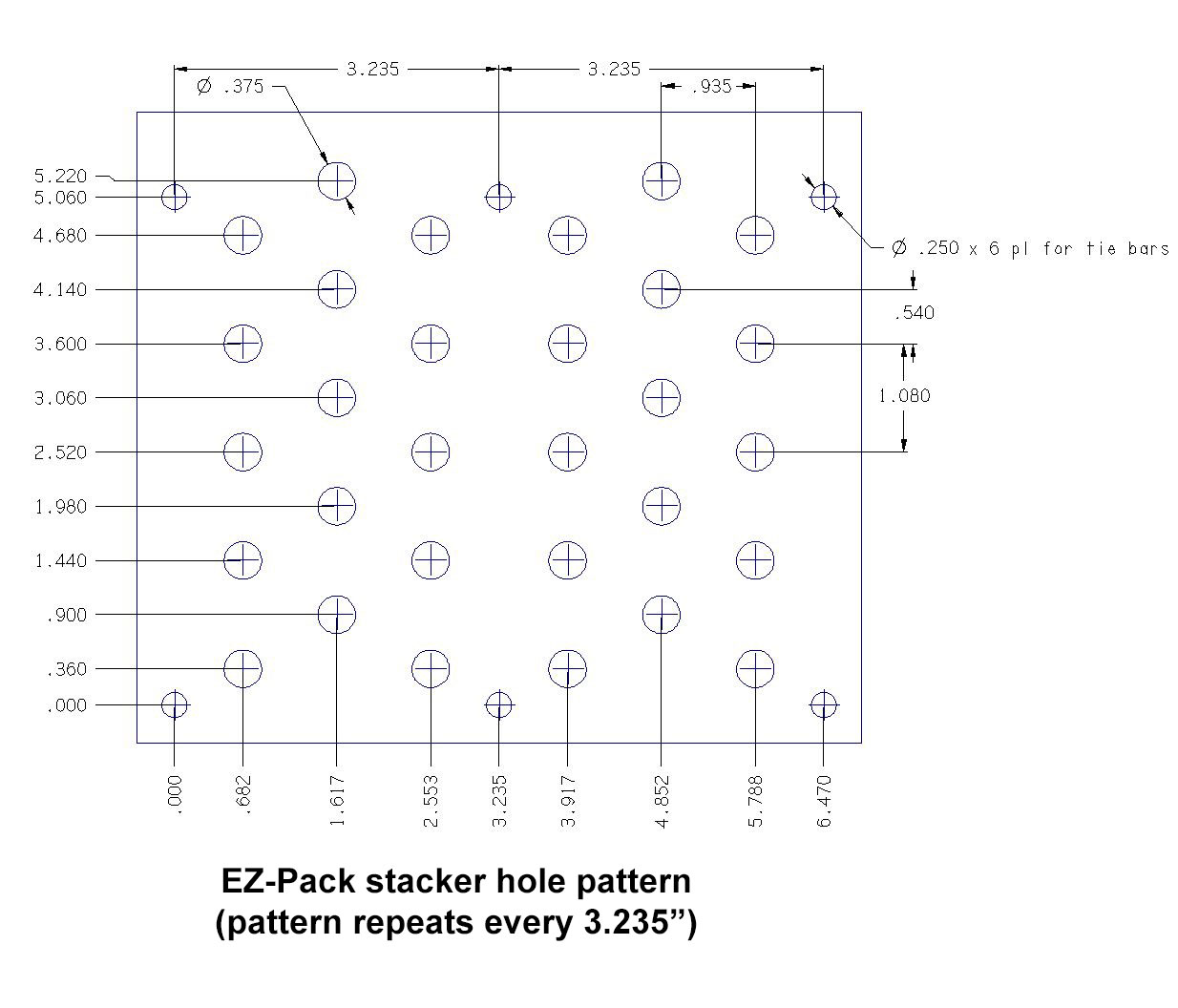

You can build most any size battery using our EZ-Pack and Stacker system. The left photo shows the Stackers that we use to make our 10S Kart battery with five EZ-Packs in two rows. These Stackers have quick change battery mounts built in and a handle. The two outside Stackers are grooved to accept a slide-in terminal cover. The right image represents how a two row sandwich is assembled. Stackers for the large batteries used in full size EVs or power storage systems can have hard mount points built in or be made without mounts if you are planning to put them in a battery tunnel or tray. We generally make the Stackers from 3/8” polypropylene sheet, but other materials are suitable, such as 10mm Baltic birch plywood or G10 fiberglass board.. To make a battery with a single row of EZ-Packs you need just two Stackers, one on each side of the EZ-Packs. Every row of EZ-Packs you add uses another stacker. You will also need enough Tie-Bars of the proper length to hold the sandwich together. Once you decide how many EZ-Packs you’ll need and the layout that fits your application, if you need custom made Stackers send us a sketch and we’ll quote, or you can download our hole pattern drawing and have a local machine shop make them for you. Each EZ-Pack adds 3.235” of length. Our generic 14” Stacker (p/n EZ-14) will support 4 EZ-Packs to make a (nominal) 12V battery. Add third a Stacker and another row of 4 EZ-Packs to make a 24V battery. Our 28″ stackers p/n EZ-28 will support 8 EZ-Packs per row. A two-row battery made using three 28″ Stackers will contain 16 EZ-Packs and provide 52.5V in a 64 lb battery. Each EZ-Pack of cells adds about 4 lb to the battery mass. We suggest that if you’re going to be handling the batteries often, better to have a few smaller ones that can be carried easily instead of one so heavy you’ll need help.

Stacker Hole Pattern:

Reviews

There are no reviews yet.